Shop

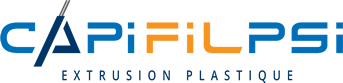

750 g GLISS’ PETG 3D printing filament

48,96€ TTC 40,80 HT

PETG GLISS’ 3D filament has excellent sliding properties and high resistance to wear. This filament is suitable for producing mechanical parts and functional prototypes that are subject to friction or need to slide.

Low friction coefficient. Slides with minimal friction and wear. Made in France by Capifil.

Natural colour (white), available with diam. of 1.75 mm

To order large volumes or specific materials, contact us for a customised quote.

Capifil PETG Gliss 3D Filament technical data sheet

PETG GLISS’ 750g filament is modified PETG for effective sliding.

Made in France by Capifil.

Features:

- This filament has a low friction coefficient equal to POM plastic and five times less than standard PETG, as demonstrated in a standardised laboratory test.

- Sliding surface

- Excellent rigidity

- Similar printing functionality to POM filament

- White, natural appearance

Applications:

- Prototypes, mechanical parts, and model parts subject to friction that require sliding properties

- Gears or parts in contact subjected to movement

- Everyday objects

Technical properties:

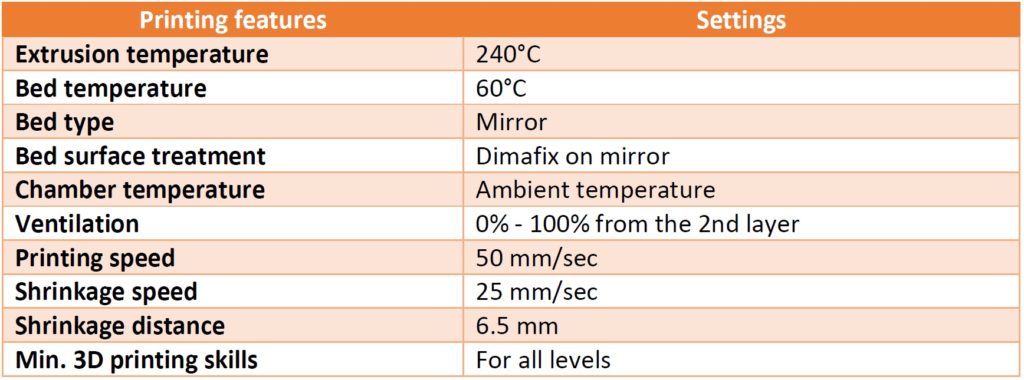

3D PETG GLISS’ filament is ideal for professional and home 3D printing. Suitable for 3D printers with FFF (Fused Filament Fabrication) technology with a heated bed.

Tips:

- Recommended melting temperature of 240° to avoid stringing or remove small threads after production.

- No need for a printer with a closed chamber.

- Two-year warranty.

Download the Capifil 3D PETG GLISS’ filament technical data sheet

Experts in plastic extrusion, Capifil designs, manufactures and sells a range of 3D filaments for the production of 3D prototypes, technical parts and everyday objects. Our range of filaments is designed for demanding professionals in the industrial sector, R&D departments and designers, as well as users of home 3D printers.

All our 3D printing filaments are designed, made and packaged in France in our plastic extrusion factory in Cras, in the Isère region.