25 years of experience and innovation

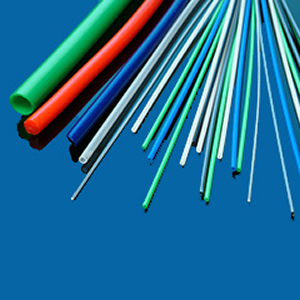

An expert in plastic extrusion and co-extrusion, Capifil offers a wide range of plastic products: plastic sheathing, tubes, rods, piping, filament, granulate... all products are custom-extruded to meet your requirements.

Innovation and expertise

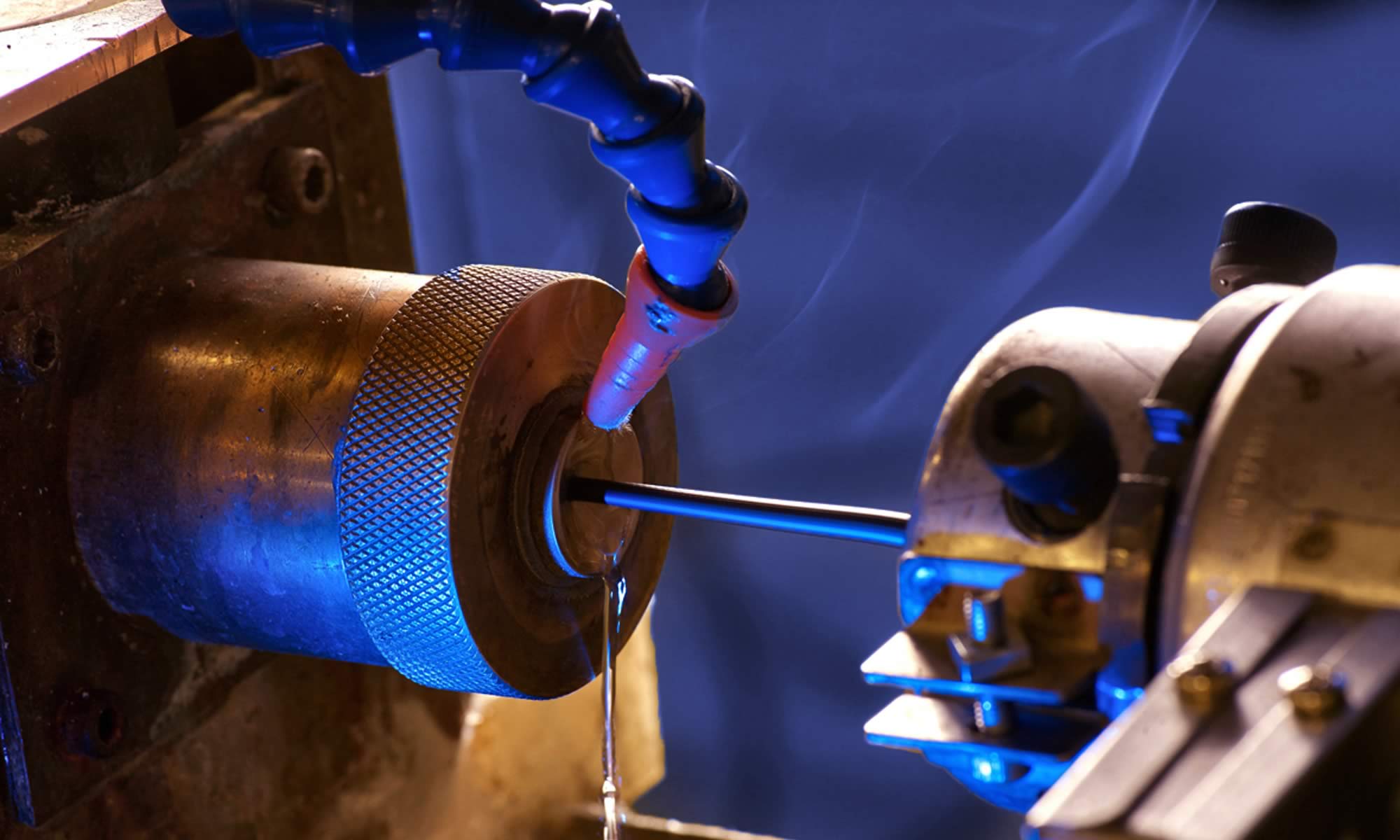

- Technical expertise in plastic extrusion: Capifil assists you with the design, industrialization and manufacturing of your extruded products.

- Control over the entire manufacturing process, from the choice of forms and materials to the final quality inspection.

- A team of seasoned professionals who make customer satisfaction a priority.

Quality, made in France

- 100% of manufacturing carried out internally

- Strict quality monitoring at every manufacturing stage; ISO 9001 certification since 1998.

- 12 plastic extrusion lines. Sheathing for all kinds of wires and cables, manufacturing of tubes, rods, piping, 3D filament, granulate...

- A wide range of complementary finishings online: branding, mitre cuts, special packaging...

A well-performing industrial structure

- A believer in Lean Manufacturing and a flexible, responsive structure.

- The flexibility required to handle long or short series with tight deadlines.

- The ability to find fast, high-quality, economically sound solutions.

Capifil in figures

years

of experience

plastic

extrusion lines

production

hours / year

Assisting in

your development

Today, the challenges of technological markets require higher-than-standard quality, as well as collective intelligence. The notion of co-development plays a key role. Capifil develops, for you and in collaboration with you, innovative, effective solutions that meet your specific needs. Our technical office is equipped to assist you at any development stage:

« Innovation is a blend of research,

marketing, instinct, imagination and industrial bravery. »

Our products

Capifil offers a wide range of extruded products, produced through the processing of traditional materials: flexible or rigid PVC, PE, homo- or copolymer PP, cellulose acetate... Technical materials: POM, homo- or copolymer, PA6, PA6/6, standard and MOS² filled, PS, PA 11 and 12, standard and plastic, graphite filled, ABS, PC, TPE, PU, PEI... Innovative materials and alloys with improved performance.